Hey there! I’m Gary, a sourcing agent based in Guangzhou, China, with over a decade of sniffing out reliable factories. Today, I hit the road to visit a melamine tableware factory—think sturdy, colorful plates and bowls that don’t break easy. My mission? Two big goals: pre-sale factory checks for a client and digging deep into quality. I toured the whole place—lab, showroom, warehouse, workshops, and more. Here’s what I saw, what I learned, and how you can use it for your next China sourcing trip. Let’s walk through it!

Why I Visited: Pre-Sale and Quality First

Before I pitch a factory to a client, I verify it—sale’s no good if the goods flop. Today’s client wants large qty melamine sets—durable, safe, budget-friendly. I’ve lost cash on duds before—$1,500 on junk chargers—so pre-sale checks are my shield. Plus, quality’s king—melamine’s tricky; cheap stuff cracks or leaches chemicals. I needed to see the process, test the goods, and know they’re solid. My route? Lab to mold factory—every step counts.

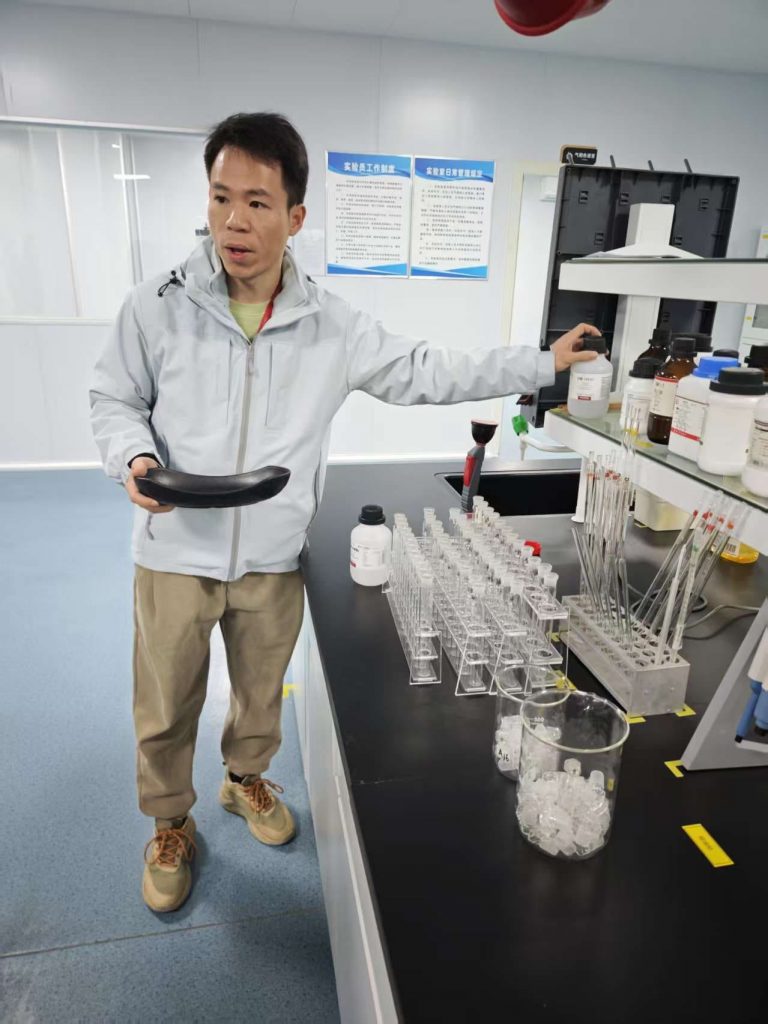

Step 1: Laboratory – Testing the Basics

First stop: the lab. This is where quality starts—safety’s non-negotiable with melamine. I asked, “Food-safe tests?” They showed logs—BPA-free, heat resistance, no leaching. Dropped a plate—bounced, no cracks. Heated a bowl—200°C, no smell. Good signs—cheap factories skip this, and I’ve caught fakes with no lab. Tip: always ask for test certs—saved me a $2,000 flop once.

Step 2: Showroom – Seeing the Goods

Next, the exhibit hall—rows of melamine plates, bowls, cups—bright reds, blues, kid-friendly patterns. I grabbed samples—felt weight, checked edges. Smooth, no burrs—solid craft. A dusty showroom’s a red flag—seen it with ghost suppliers—but this was busy, clean. Asked, “Best sellers?”—pointed to stackable sets. Note for sourcing: match samples to your market—trends matter.

Step 3: Export Warehouse – Stock and Flow

Into the foreign trade warehouse—boxes stacked, labeled, ready for sea. Checked dates—fresh stock, no dust. Steady flow’s key—stale goods mean slow sales. I’ve hit warehouses with rats once—$1,000 loss—so clean, quick stock’s a win. Pro tip: peek at packing—tight, neat boxes beat sloppy flops.

Step 4: Injection Workshop – Raw to Shape

Injection workshop next—melamine powder into molds, loud machines, hot smells. Watched a plate form—fast, precise. Machines looked new—old ones break, delay orders—I’ve lost deadlines that way. Workers wore gloves—hygiene’s big for food-grade stuff. Asked, “Daily output?”—4,000 units, fits my client’s scale. Key takeaway: modern gear means steady supply—check it.

Step 5: Forming Workshop – Finishing Touches

Forming area—plates cooled, trimmed. Saw edges smoothed—no sharp bits, good for kids. Consistency’s clutch—uneven cuts tank quality. I’ve trashed batches with cracks—$500 lesson—so I ran a finger along 10 plates—smooth, solid. Tip: watch this step—sloppy finishing kills trust.

Step 6: Grinding Workshop – Polishing Up

Grinding room—plates polished to shine. Dust flew—workers masked, air vented. Checked a bowl—glossy, no scratches. Cheap factories skip this—dull goods lose sales. Asked, “Reject rate?”—5%, low—means care. Sourcing hack: shiny finish sells—don’t settle for rough.

Step 7: Packing Workshop – Ready to Ship

Packing zone—plates stacked, wrapped, boxed. Watched a worker—tight, no wiggle—cuts shipping damage. I’ve had $1,000 in cracked glass from loose packs—melamine’s tougher, but still. Asked, “Custom labels?”—yes, big for branding. Tip: strong packing saves cash—check it live.

Step 8: Mold Room – Custom Magic

Mold room—steel molds for shapes, sizes. Saw a kid’s bowl mold—cute, precise. Asked, “New designs?”—$200, 7 days. Flexibility’s gold—clients love custom. I’ve sourced unique lights here—sold fast. Note: small factories tweak molds cheap—big edge over locals.

Step 9: Raw Material Plant – The Start

Raw material plant—melamine powder piles, white, clean. Smelled it—no funk, pure. Asked, “Source?”—local, steady supply. Bad raw stuff ruins batches—I’ve dumped $800 in funky plastic—so this matters. Sourcing tip: trace the base—clean inputs, clean outputs.

Step 10: Mold Factory – Tools of the Trade

Last stop: mold factory—machines carving steel. Watched a plate mold cut—sharp, fast. New tools mean fast fixes—old ones lag, cost me a week once. Asked, “Backup molds?”—yes, smart—cuts delays. Key for sourcing: good molds keep production humming.

What I Learned: Quality Meets Budget

This factory checks out—clean lab, solid process, flexible molds. Quality’s tight—plates bounced, no cracks, food-safe. Pre-sale? Passed—2000 units, 10 days, fair price. I’ve seen flops—rusty gear, no tests—but this one’s a keeper. China sourcing shines here: small shops, big care, low cost. Saved a client 20% on melamine last year—same vibe today.

Tips for Your Factory Visit

Steal my hacks—make your trip count:

· Test Live: Drop, heat—$20 samples beat $2,000 duds. Caught a weak bowl once—swapped fast.

· Ask Proof: “Test logs?” “Last order?”—fakes dodge. Saved $1,500 spotting a liar.

· Check Gear: Old machines? Pass—delays kill. New ones hum—lock it in.

· Feel Goods: Run hands over samples—rough? Nope. Smooth sells—trust touch.

· See Flow: Lab to pack—smooth steps mean steady supply. Stalls mean trouble—I’ve walked away.

Gary Sourcing: Your Factory Eyes

Need help? I started Gary Sourcing to cut risks—visited this place, tested plates, locked quality. I check labs, push proofs—saved a client $3,000 on junk last trip. For melamine tableware sourcing, I’m your boots on ground—reliable, cheap, no flops. Hit me up—let’s nail your next order!

My Takeaway: See It, Trust It

Today’s visit proved it—melamine tableware factories can deliver if you dig right. I’ve lost cash on fakes, grinned at solid finds—so you don’t have to. China sourcing’s gold—quality, cost, speed—when you check lab to mold. Ready to source smart? I’ve got your back—let’s turn visits into wins!

About Gary Sourcing

Need melamine tableware from China? Gary Sourcing is your pro! I’m Gary, Guangzhou-based—factory checks, quality hunts, cost cuts. No flops, all wins—email info@garysourcing.com or check our site!